Displacements are the absolute change in position of a point on the object deflection is the relative change in external displacements on an object strain is the relative internal change in shape of an infinitesimally small cube of material and can be expressed as a non dimensional change in length or angle of.

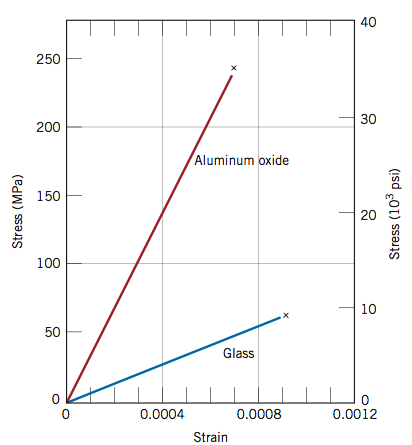

Engineering stress strain curve for ceramics.

The strain used for the engineering stress strain curve is the average linear strain which is obtained by dividing the elongation of the gage length of the specimen d by its original length.

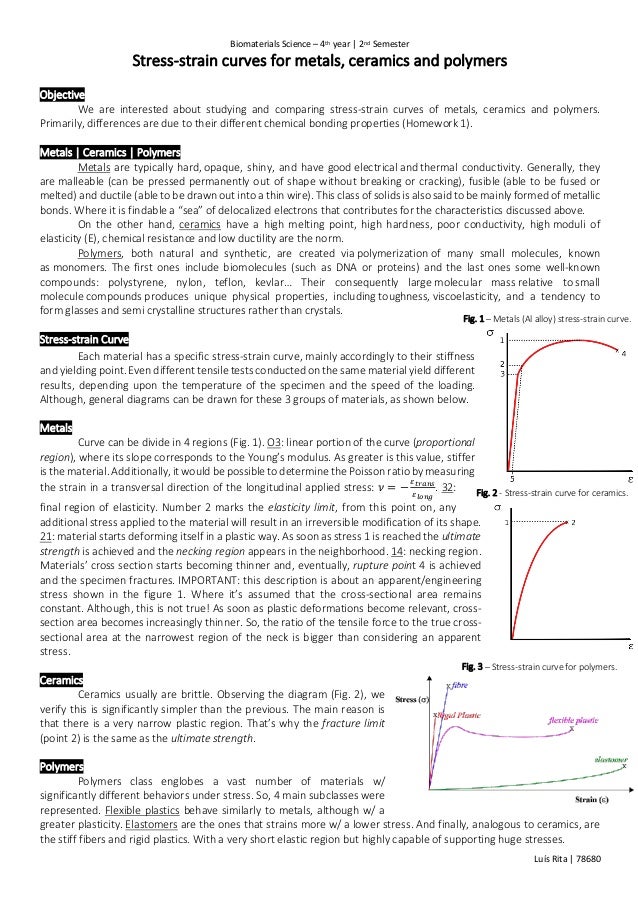

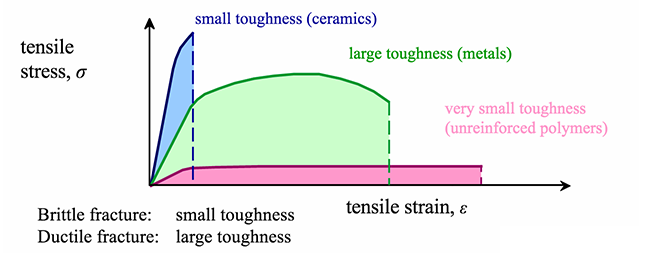

With a very short elastic region but highly capable of supporting huge stresses.

In engineering deformation refers to the change in size or shape of an object.

For brittle ceramics a three point bending apparatus shown in the figure below is used determine the stress strain behavior and the measurement results are used to calculate an equivalent modulus of elasticity.

An example of the engineering stress strain curve for a typical engineering alloy is shown in figure 1.

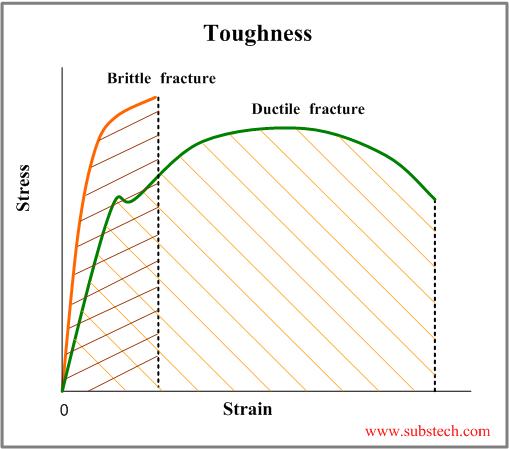

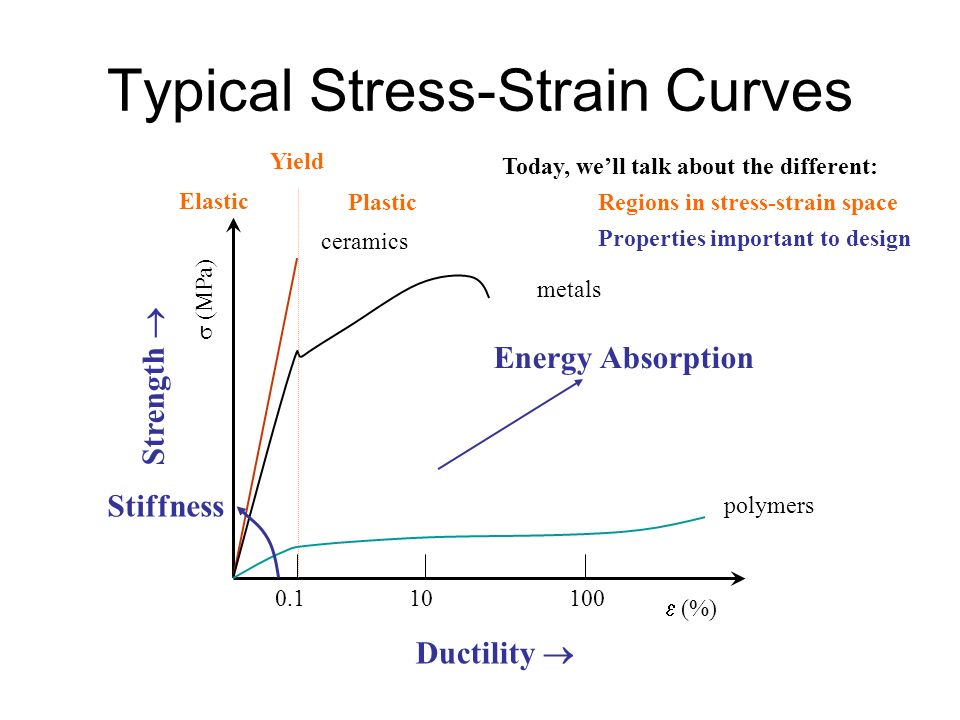

In engineering and materials science a stress strain curve for a material gives the relationship between stress and strain it is obtained by gradually applying load to a test coupon and measuring the deformation from which the stress and strain can be determined see tensile testing these curves reveal many of the properties of a material such as the young s modulus the yield strength.

The elastic modulus the yield strength the ultimate tensile strength and the fracture strain are all clearly exhibited in an accurately constructed stress strain curve.

From it some very important properties can be determined.

2 stress strain curve for ceramics.

If we are talking about stressing the material and having it return to its original state we are talking about the material remaining in the elastic region of the stress strain curve.

With one simple graph an engineer can understand many properties of a material under load applied force.

1 metals al alloy stress strain curve.

And finally analogous to ceramics are the stiff fibers and rigid plastics.

Elastomers are the ones that strains more w a lower stress.

It turns out that we can get the energy of elasticity by taking the area under the curve of the stress strain curve.